Main applications

- Evaluating the performance of Kinetic Hydrate Inhibitors (KHIs), by measuring the induction time, rate of hydrate formation, and pressure drop due to hydrate formation.

- Evaluating the performance of Anti-Agglomerants (AA) in preventing gas hydrate problems, by measuring the torque applied to the mixer, and rate of hydrate formation.

- Determining the effect of natural inhibitors and emulsions in preventing gas hydrate problems.

- Simulating various pipline scenarios, such as flowing, shut-in and start-up.

- Investigating the kinetics of gas hydrate formation and dissociation.

- Measuring the hydrate stability zone of various fluid systems (e.g., gas, gas condensate and oil systems).

- Determining the effect of various hydrate inhibitors (e.g., salts and/or organic inhibitors) on the hydrate stability zone.

- Qualitative measurement of viscosity and transportability of fluids containing hydrates and/or wax.

Operating conditions

Pressure: up to 6,000 psia (40 MPa)

Temperature: from –30 to 75 ºC

Description

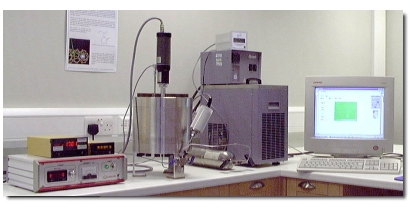

The rig consists of a high-pressure vessel (40 MPa) with a 2.4 litre volume. The cell temperature is controlled by circulating coolant inside a jacket in the cell wall, and measured by a thermocouple to an accuracy of 0.1 K. The cell pressure is monitored by a quartzdyne pressure transducer (accuracy of 0.007 MPa). A magnetic stirrer with adjustable rotation speed (i.e., rpm) is used to agitate the test fluids. The torque required to drive the stirrer at a constant speed is measured and related to the viscosity of the system. A computer is used to collect data for pressure, temperature and torque.

The rig consists of a high-pressure vessel (40 MPa) with a 2.4 litre volume. The cell temperature is controlled by circulating coolant inside a jacket in the cell wall, and measured by a thermocouple to an accuracy of 0.1 K. The cell pressure is monitored by a quartzdyne pressure transducer (accuracy of 0.007 MPa). A magnetic stirrer with adjustable rotation speed (i.e., rpm) is used to agitate the test fluids. The torque required to drive the stirrer at a constant speed is measured and related to the viscosity of the system. A computer is used to collect data for pressure, temperature and torque.